The art of

manufacturing

You are welcome to get acquainted with our production capabilities and see for yourself the high-quality products we can offer.

Assembly plant

MACHINE PARK IN OUR PRODUCTION PLANT ARTPLEX KOBYŁKA

Cutting precision, infinite number of custom patterns

various materials, including: wood, plastic and metal.

These plotters are used to produce small ornamental elements, furniture details, and letters of different sizes. Their large working area and milling height (WDH 2500x1500x300 mm) also allow for the processing of larger components, such as thermoforming molds.

Thanks to their cutting and creasing capabilities, they are indispensable in creating non-standard, personalized displays (e.g., PP clip strips, thin foil boxes).

Various materials, thousands of possibilities

In our woodworking facility, we work with various materials, such as:

Solid wood: We create structures from different types of solid wood, such as oak, beech, ash or pine.

Particle boards and MDF: We cut, mill, and laminate these materials, producing display stands of various sizes, shapes and patterns.

Wood veneers: We have machines for precisely applying wood veneers to various surfaces so that we can achieve the effect of wooden elements without having to use solid wood.

Plastics: We process plastics such as PVC, acrylic, or polycarbonate. This enables us to create transparent, colourful or matte parts for furniture and promotional displays.

Our machines include:

with a curvilinear edge banding unit: This machine allows us to work in 5 axes, enabling the creation of complex shapes and details. With the curvilinear edge banding unit, we can precisely laminate curved surfaces.

Combining drilling, milling, and engraving functions, this machine allows us to create various patterns and details on furniture and promotional displays.

This machine enables precise edge banding on the surfaces of promotional furniture. We can finish the edges with plastic, wood veneers, or metal elements.

We use this machine to achieve even and smooth surfaces on wooden and plastic furniture parts.

This automatic saw allows us to make precise cuts on material boards, ensuring the perfect fit.

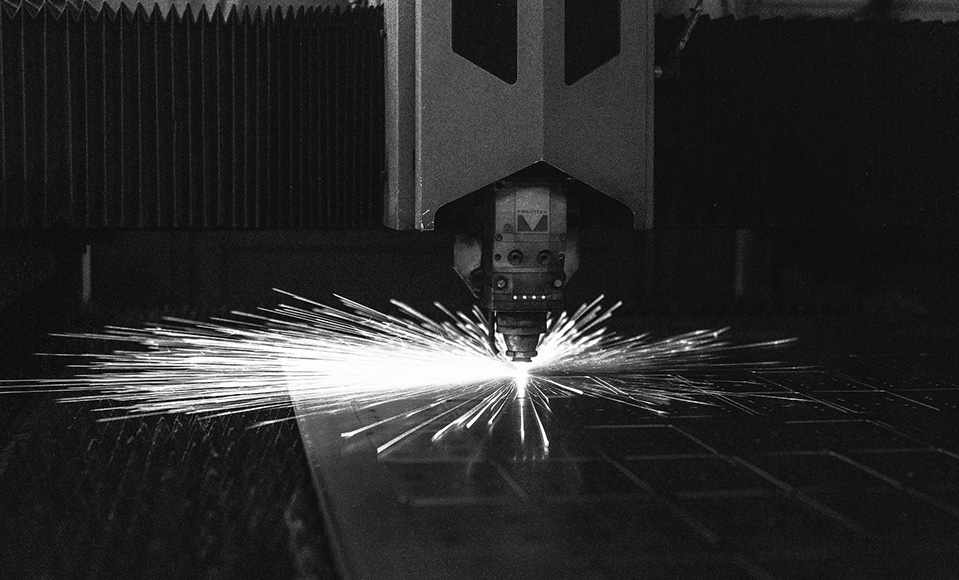

Cutting, engraving, and bending of various materials

Our machines include:

SEI MERCURY 609 Cutting Laser

- Large working area of 2000x1500 mm

- Capable of cutting materials up to 20 mm thick

- Used for producing BLU panels with a unique lighting optimization method.

SEI NRG LASER 1610 Cutting and Engraving Laser

- Offers a working area of 1000x1590 mm

- Utilized for both precise cutting of various materials as well as for high-resolution engraving

SEI MERCURY 609 and SEI NRG LASER 1610 Cutting Lasers

-

Suitable for cutting materials such as wood, plywood, PC, PMMA, PETG, laminated boards, fabrics, felt, leather, rubber, and many others up to 20 mm thick

-

Enables the creation of a variety of products such as furniture components, decorative panels, signs, stickers, labels, and many more

CO2 GCC EXPLORER II Cutting and Engraving Laser

- Ensures precise cutting and engraving on different materials

- Ideal for processing materials like acrylic, wood, plywood, fabrics, felt, leather, rubber, paper, and many more

- Used to create decorative elements, ornamental details, signs, logos, packaging, and many other products

Bending Machines

- We have 20 thermal bending machines for plastics such as PVC, PC, PMMA, PETG, and others

- These machines allow for flexible and precise bending of plastics, even up to 3 meters long

- Used to create bent elements, price strips, profiled panels, decorative shapes, stands, and many more

High-quality printing on various materials

Our machines include:

UV Plotter Océ ARIZONA 660GT

- Enables printing on glass, plastic, metal, and wood

- Provides durable and scratch-resistant prints with vibrant colors and crisp quality

Solvent Plotter Roland VersaCAMM Print&Cut VS-640ic

- Used for printing on materials such as foil, banners, posters, and many others

- Provides durable and scratch-resistant prints with vibrant colors and crisp quality

- Ensures durable and waterproof prints resistant to weather conditions and sunlight exposure.

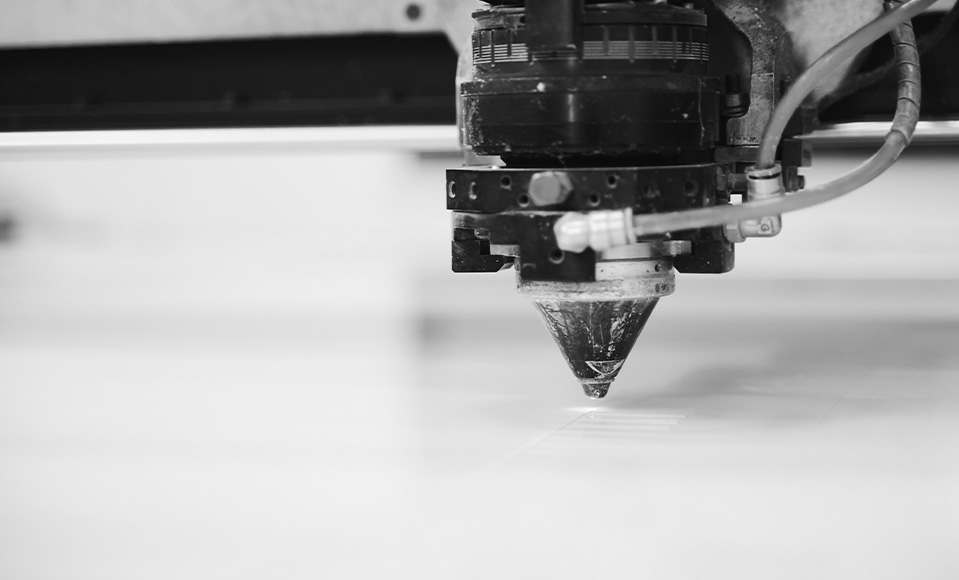

A variety of shape options in different sizes

VACUUM THERMOFORMER

TF MILLENIUM 200 PLUS

The machine allows for processing various materials, such as plastics (ABS, PC, PVC, etc.), laminated composites (wood, plywood, decorative laminates, etc.) and thermoformable materials (PVC foam, polyurethane foam, thermoplastic elastomers).

Clients can be confident that they will receive accurate and repeatable shapes that meet project requirements, including precise details, smooth surfaces and perfect project alignment.

Automatic forming, vacuuming, and cutting speed up our workflow and minimize the risk of human error.

The machine enables cost savings on raw materials through precise forming and reducing material losses. This is particularly important when working with expensive or unconventional materials.

MACHINE PARK IN OUR PRODUCTION PLANT ARTPLEX PŁOCK

High Precision Work

Flexibility

Speed and repeatability of production

High-Quality workmanship

Utilization of Various Materials

Laser welding

- High precision and welding quality, ensuring flawless and durable welds.

- Capable of welding various materials: steel, aluminum, copper, and titanium.

Laser engraving and cutting of profiles and tubes, used for the production of:

- Furniture: retail (shelves, racks, stands, display cases, reception desks), office and conference furniture (desks, conference tables, file cabinets),

- Displays, panels, and advertising signs: logotypes, outdoor and indoor business signs, Other decorative elements: cutouts, patterns, stained glass windows.

The versatility of the BLM LT7 guarantees high-quality and customizable production of a wide range of furniture and decorative items.

High-precision laser cutter for processing various materials:

- Steel sheet, carbon steel, stainless steel, and other steel alloys

- Aluminum

- Copper

- Thermoplastics

The machine offers exceptional accuracy, allowing for intricate and precise cuts in the desired shapes and sizes.

Flexible bending of various types of profiles and shapes

Powder coating provides a uniform and durable painted finish resistant to scratches, corrosion, and UV radiation. We can achieve various effects, such as matte, glossy, metallic, or textured finishes.

Additionally, we have a large curing oven with working dimensions of 2000x500x1000 mm, which makes it possible to powder coat large objects or big batches of smaller items simultaneously. This ensures efficient and effective powder coating processes, resulting in high-quality and long-lasting finishes.

- Carbon Steel:

Up to a certain thickness, e.g., up to 20 mm. - Stainless Steel:

Up to a certain thickness, e.g., up to 12 mm. - Aluminum:

Up to a certain thickness, e.g., up to 10 mm. - Copper:

Up to a certain thickness, e.g., up to 6 mm. - Plastics:

Up to a certain thickness, e.g., up to 12 mm.